Contact Us

- Room 2105, Xingda Garden, No. 122 Tianhua Middle Road, Xingsha Street, Changsha County, Hunan Province

- [email protected]

- +8617788962926

Full Automatic High Speed Solid Drinking Packaging Machine

It is use volumetric cups measure the weight and dosing.Suit filling granule product salt,sugar,washing powder,spice etc.

Description

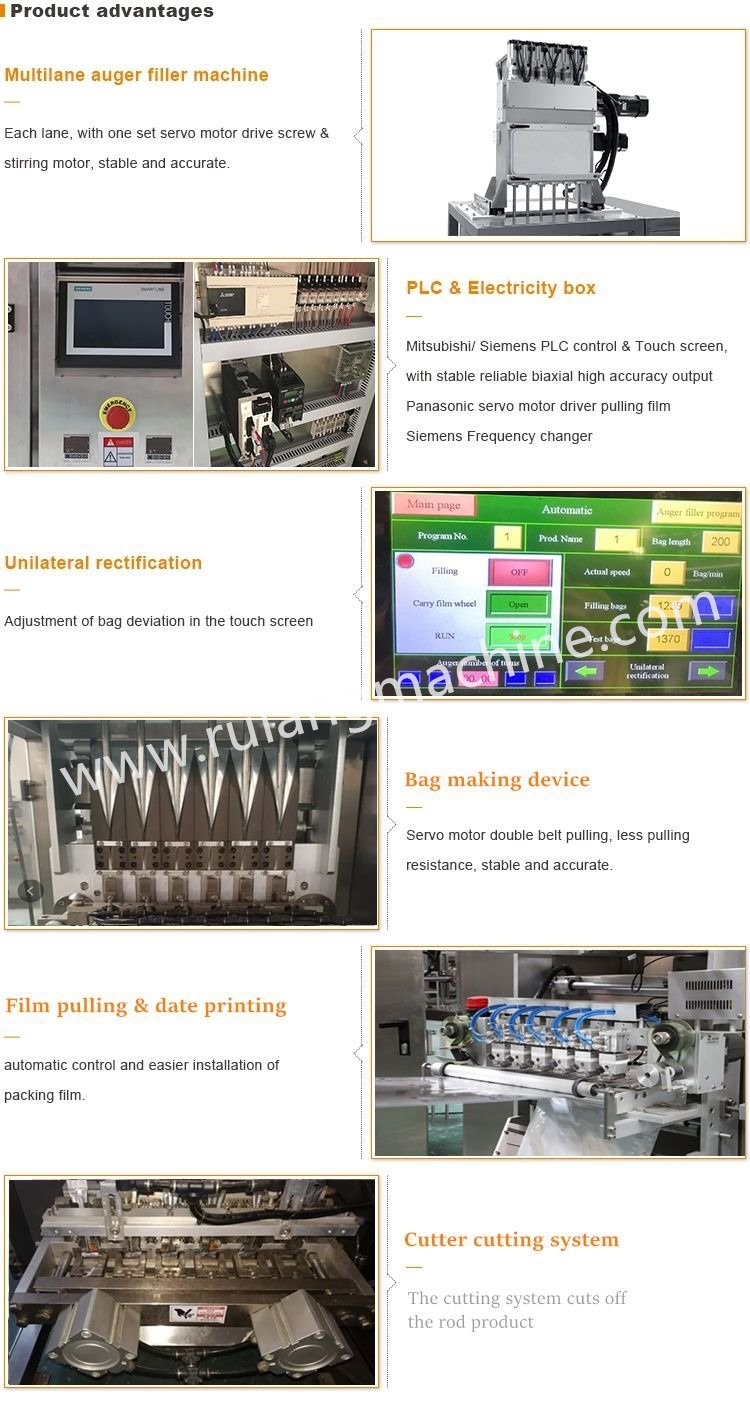

Advantage

Solid drinking packaging machines offer many advantages for packaging companies. These machines are designed to efficiently package liquids such as water, juice, and milk into bottles or other containers. Here are some of the advantages of using solid drinking packaging machines:

1. Efficiency: One of the biggest advantages of using solid drinking packaging machines is that they are designed to handle high volumes of liquid packaging. This means that packaging companies can produce a large number of packaged liquids in a short amount of time, which can help to increase production efficiency.

2. Consistency: Solid drinking packaging machines are designed to package liquids in a consistent manner. This means that each bottle or container will contain the same amount of liquid and will be filled to the same level. This helps to ensure product quality and customer satisfaction.

3. Hygiene: Solid drinking packaging machines are designed to be hygienic, which is important when packaging liquids. These machines are made of materials that are easy to clean, and they have features that prevent contamination of the liquid being packaged. This helps to ensure that the packaged liquids are safe for consumption.

4. Versatility: Solid drinking packaging machines can be used to package a variety of liquid products, including water, juice, milk, and other beverages. This makes them a versatile option for packaging companies that produce a range of liquid products.

5. Cost-effective: Using solid drinking packaging machines can help to reduce packaging costs. These machines are designed to be efficient, which means that packaging companies can produce more packaged liquids in a shorter amount of time, reducing labor costs. Additionally, these machines are designed to minimize waste, which helps to save on materials costs.

Overall, solid drinking packaging machines offer many advantages for packaging companies. From increased efficiency to improved product quality, these machines are an excellent investment for any business that produces liquid products.

Introduction

Solid drinking packaging machine is a crucial aspect of modern packaging technology, providing efficient and effective packaging solutions for various kinds of beverages. The popularity of packaged beverages, especially in the form of cans and bottles, has increased tremendously, and solid drinking packaging machines have played a significant role in meeting the needs of the industry.

These machines are designed to ensure that beverages are well-packaged, secure and easy to handle, and are compatible with their intended distribution channels. They come in a variety of sizes, from small manual machines to large automated ones, and can package various kinds of beverages, including juices, soft drinks, energy drinks, and water.

One of the key benefits of solid drinking packaging machines is their ability to maintain the quality of the beverages during the packaging process. These machines are optimized to minimize contact between the beverage and the external environment, reducing the chances of contamination and ensuring that the beverages remain fresh for longer periods.

Moreover, solid drinking packaging machines are efficient and cost-effective, providing reliable, high-quality packaging solutions while minimizing production costs. They can handle large volumes of beverages, and the automated versions are designed to operate with minimal human intervention, reducing labor costs.

Another benefit of solid drinking packaging machines is their flexibility. They can be customized to fit different packaging needs, and can handle a wide range of bottle sizes and shapes. This flexibility makes them suitable for use in various industries, including food and beverages, pharmaceuticals, and personal care products.

Overall, solid drinking packaging machines have revolutionized the packaging industry, providing efficient, safe and cost-effective packaging solutions for a wide range of beverages. They have set new standards in packaging technology, and their continued development is set to usher in a new era of packaging efficiency and effectiveness.

Sample bags

|

Model |

RL-420-4K |

RL-420-6K |

|

Bag length |

30-140mm |

30-140mm |

|

Bag width |

10-50mm |

10-32mm |

|

Max roll film width |

440mm |

440mm |

|

Packing speed |

30-50bags/min/lane |

30-50bags/min/lane |

|

Air pressure |

0.65mpa |

0.65mpa |

|

Air consumption |

0.2m³/min |

0.2m³/min |

|

Power supply |

220VAC/50Hz |

220VAC/50Hz |

|

Power |

2.0 KW |

2.0 KW |

|

Overall size |

1100*990*2100mm |

1100*990*2100mm |

|

Net weight |

400 kg |

450 kg |

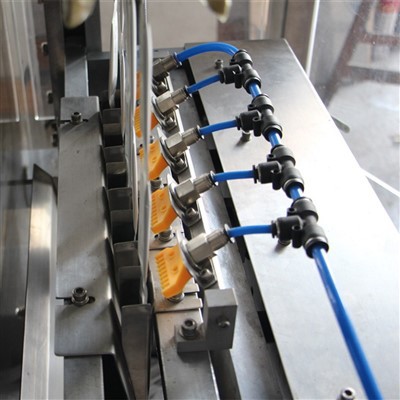

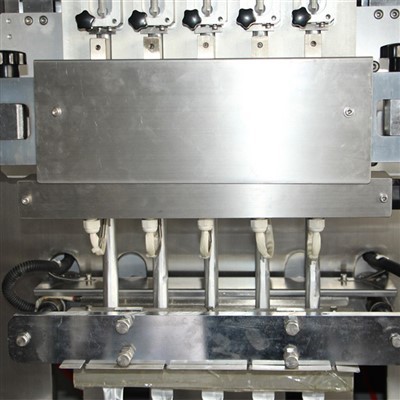

Machine detail pictures:

FAQ

1) Q: How do I choose the right type of machine?

A: Please provide the following info for us to make a solution to meet your unique product packaging requirements with the lowest costs.

* What is the product (picture or short video clip better);

* Packaging bag size (length/width), volume in each bag;

* Bag type:

- Premade bag (doy bag, block bottom bag, gusseted bag, 4 side seal bag, etc); with or without euro hole, easy tear open; plastic bag or paper bag;

- Packaging film form-fill-seal bag (3 side seal bag, 4 side seal bag, pillow bag, stick pack, etc); with or without euro hole, easy tear open.

* Outputs requirements (speed)

* We will send you machine working video for your reference.

2) Q: How can I trust you for the first time business?

A: We are a registered company in China Industry and Commerce Bureau, and a certified member by Alibaba. If you don't trust us, we can use Alibaba's Trade Assurance service, which will fairly safeguard your rights and money throughout the transaction process.

3) Q: How do I place an order and how is it completed?

A: When you are satisfied with our quotation terms and pre-sales service:

- Both sides sign a contract or PI.

- Customers arrange the deposit payment.

- Our factory arranges production.

- Test & trial run the machine after it is finished

- Inspection by customers or their third parties or videos.

- Customers arrange the balance payment.

- Arrange to ship.

- Help customers with the machine installation.

4) Q: How do I contact you?

A: - Leave messages on this page and click "send".

- Email, WhatsApp, Wechat, Skype, QQ, phone, etc.

Hot Tags: full automatic high speed solid drinking packaging machine, China full automatic high speed solid drinking packaging machine manufacturers, suppliers, factory, bottle washing filling capping machine, ferrule label printing machine, postage label machine, food label printer machine, clothes washing machine, accutek labeler

You Might Also Like