Contact Us

- Room 2105, Xingda Garden, No. 122 Tianhua Middle Road, Xingsha Street, Changsha County, Hunan Province

- [email protected]

- +8617788962926

Paste packing machine is a specialized industrial equipment designed for the precise and efficient packaging of pasty or viscous substances. This type of packaging machinery plays a crucial role in various industries, including food, pharmaceuticals, cosmetics, and chemicals, where products such as sauces, creams, gels, pastes, and similar viscous materials need to be accurately measured and sealed into containers.The paste packing machine typically consists of several key components that work in harmony to ensure a seamless packaging process. A product hopper holds the paste or viscous substance, and a dosing system precisely measures and dispenses the required quantity into the packaging material. The packaging material, often in the form of pre-formed pouches or containers, is then filled and sealed using mechanisms such as heat sealing or ultrasonic sealing.

Advantages of Paste Packing Machine

Accurate Dosage And Filling

Paste packing machines are equipped with precision dosing systems, ensuring accurate and consistent filling of paste-like products into packaging containers. This accuracy is crucial for maintaining product quality and meeting dosage specifications.

High Efficiency And Productivity

These machines are designed for high-speed operation, contributing to increased production efficiency and throughput. The automated filling and sealing processes streamline the packaging line, reducing manual labor and boosting overall productivity.

Versatility In Packaging Formats

Paste packing machines can handle various packaging formats, including tubes, sachets, bottles, and jars. This versatility allows manufacturers to adapt to different product sizes and packaging requirements, catering to diverse market demands.

Ease Of Operation And Changeover

Paste packing machines are often equipped with user-friendly interfaces, allowing for easy operation and control. Additionally, they may have quick-changeover features, enabling efficient adjustments to accommodate different paste products or packaging formats.

Automatic Sauce Packing Machine

Automatic Sauce Packing MachineAn automatic sauce packing machine is a type of packaging machinery specifically designed to

Add to Inquiry Full Automatic Chilli Sauce Paste Sachet Packaging Machine

Full Automatic Chilli Sauce Paste Sachet Packaging MachineThe Full Automatic Fruit Jam Vertical Forming Filling Sealing Machine is a state-of-the-art

Add to Inquiry Full Automatic Fruit Jam Vertial Forming Filling Sealing ...

Full Automatic Fruit Jam Vertial Forming Filling Sealing ...The Full Automatic Fruit Jam Vertical Forming Filling Sealing Machine is a state-of-the-art

Add to Inquiry Multi Lane Ketchup Paste Filling And Packing Machine

Multi Lane Ketchup Paste Filling And Packing Machine1. Famous brand PLC control system, large touch screen, convenient to operate;. 2. Advanced design,

Add to Inquiry Automatic Sauce Packing Machine

Automatic Sauce Packing MachineThe Paste packing machine can utomatically measuring volume, making bags, filling, sealing,

Add to Inquiry Tomato Sauce Packing Machine

Tomato Sauce Packing Machine1. Famous brand PLC control system, large touch screen, convenient to operate;. 2. Advanced design,

Add to Inquiry Automatic Paste Packing Machine

Automatic Paste Packing MachineThe Paste packing machine can utomatically measuring volume, making bags, filling, sealing,

Add to Inquiry Ketchup Packing Machine

Ketchup Packing Machine1. Famous brand PLC control system, large touch screen, convenient to operate;. 2. Advanced design,

Add to Inquiry

Why Choose Us

High Quality

Our products are manufactured or executed to a very high standard, using the finest materials and manufacturing processes.

Professional Team

Our professional team collaborates and communicates effectively with each other, and is dedicated to delivering high quality results. We are capable of handling complex challenges and projects that require our specialized expertise and experience.

Advanced Equipment

A machine, tool or instrument designed with advanced technology and functionality to perform highly specific tasks with greater precision, efficiency and reliability.

24h Online Service

We try and respond to all concerns within 24 hours and our teams are always at your disposal in case of any emergencies.

How to Choose Paste Packing Machine

Choosing the right paste packing machine is crucial for optimizing the packaging process and ensuring the efficiency of your production line. Several factors should be considered when selecting a paste packing machine to meet the specific needs of your industry and product requirements. Here are key considerations for choosing a paste packing machine:

Type Of Paste Or Viscous Substance

Different pastes or viscous substances may have varying properties, such as viscosity, texture, and flow characteristics. Choose a paste packing machine that is specifically designed to handle the type of product you are packaging. Consider the compatibility of the dosing system with the unique properties of your paste.

Packaging Volume And Size

Determine the packaging volume and size range required for your products. Some paste packing machines are designed for small sachets or pouches, while others are suitable for larger containers such as jars or bottles. Ensure that the machine can accommodate the desired packaging formats.

Packaging Material

Consider the type of packaging material you intend to use. Different machines may be designed for specific materials such as heat-sealable films, laminates, or pre-formed containers. Ensure that the machine is compatible with the chosen packaging material to achieve optimal seals and presentation.

Accuracy And Precision

Assess the accuracy and precision of the dosing system in measuring and dispensing the paste. The machine should be capable of delivering consistent and accurate fills to maintain product quality and avoid wastage.

Sealing Mechanism

Evaluate the sealing mechanism used by the machine. Common sealing methods include heat sealing and ultrasonic sealing. Ensure that the chosen sealing method aligns with the packaging material and provides secure and airtight seals to preserve the freshness of the paste.

Production Speed

Consider the required production speed based on your manufacturing demands. Different paste packing machines have varying output capacities. Choose a machine that can meet or exceed your production requirements without sacrificing accuracy.

Ease Of Cleaning And Maintenance

Opt for a paste packing machine that is easy to clean and maintain. Hygiene is crucial, especially when dealing with pasty substances. Machines with accessible components and quick-change features facilitate efficient cleaning and reduce downtime.

Flexibility And Versatility

Consider the flexibility of the machine in handling different packaging formats, product variations, and production setups. A versatile machine can adapt to changing requirements and product lines.

Integration With Other Equipment

If the paste packing machine will be part of a larger production line, ensure that it can seamlessly integrate with other equipment such as conveyors, filling stations, and downstream packaging processes.

What Are the Main Components of a Paste Packaging Machine

Product Hopper

The product hopper is a container that holds the paste or viscous substance before it is dispensed into the packaging material. The size and design of the hopper can vary based on the production requirements and the characteristics of the paste.

Dosing System

The dosing system is responsible for measuring and dispensing the precise quantity of paste into each packaging unit. Different dosing systems may include piston fillers, gear pumps, auger fillers, or other mechanisms suitable for handling viscous materials.

Packaging Material Feeding System

This system feeds the packaging material into the machine. Depending on the machine's design, the packaging material may be in the form of pre-formed pouches, sachets, or other containers.

Forming And Sealing Mechanism

The forming and sealing mechanism shapes the packaging material into the desired container format and seals it to enclose the measured paste. Common sealing methods include heat sealing or ultrasonic sealing, and the machine may create various packaging types such as sachets, pouches, or containers.

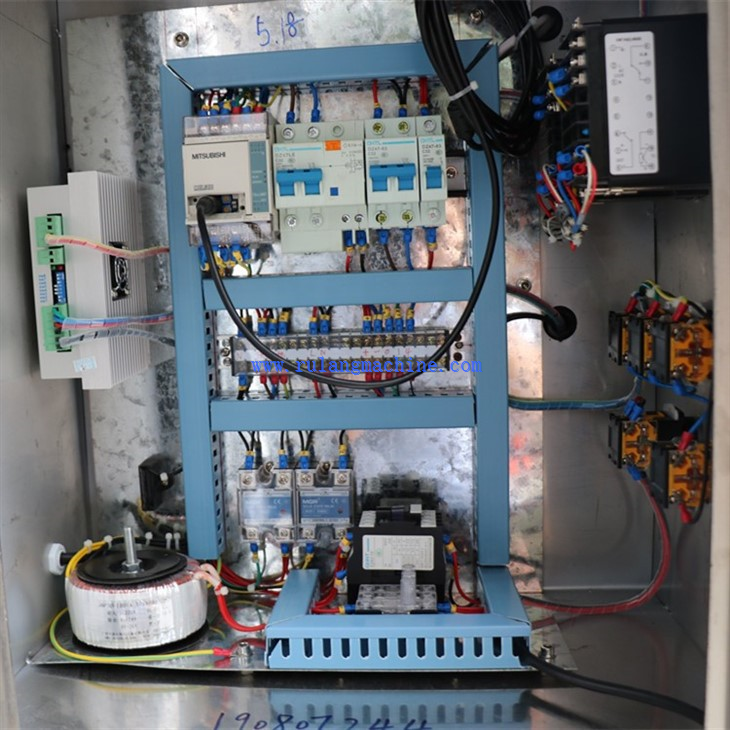

Control System

The control system oversees and coordinates the entire packaging process. It includes a human-machine interface (HMI) or control panel that allows operators to set parameters, monitor production status, and make adjustments as needed. Programmable logic controllers (PLCs) or computerized controls are often used for precision.

Conveyor System

A conveyor system transports the packaged products through various stages of the packaging process. It ensures a smooth and continuous flow, allowing for efficient filling, sealing, and subsequent processes.

Sensor And Detection Systems

Sensors are employed to detect the presence of packaging material, monitor the filling process, and ensure proper sealing. These sensors contribute to the accuracy and reliability of the machine's operation.

Date Coding And Printing System

Some paste packaging machines are equipped with date coding and printing systems. These systems mark each package with essential information such as expiration dates, batch numbers, or product codes.

Cleaning And Sanitization Components

Machines designed for applications where hygiene is critical may include components for easy cleaning and sanitization. Quick-release components, washdown-rated materials, and access points for thorough cleaning contribute to maintaining cleanliness standards.

Optional Accessories

Depending on the specific requirements, paste packaging machines may include additional accessories such as automatic feeding systems, nitrogen flushing for modified atmosphere packaging, or vision inspection systems for quality control.

How Do You Troubleshoot a Paste Packaging Machine

Refer To The User Manual

Consult the user manual or technical documentation provided by the machine manufacturer. The manual often contains valuable information about common issues, troubleshooting steps, and maintenance procedures specific to the machine model.

Inspect For Obvious Issues

Conduct a visual inspection of the paste packaging machine. Look for any loose components, damaged parts, or foreign objects that may be causing issues. Address any obvious problems before proceeding with more in-depth troubleshooting.

Check Power And Electrical Connections

Ensure that the machine is properly powered and that all electrical connections are secure. Check for blown fuses, tripped circuit breakers, or loose wires. Verify that the power supply meets the machine's requirements.

Review Control Panel Settings

Examine the settings on the machine's control panel. Verify that the parameters, such as dosing volumes, sealing temperatures, and filling speeds, are configured correctly. Make adjustments if necessary, ensuring that settings align with the product and packaging requirements.

Inspect Sealing Mechanism

If the machine is equipped with a sealing mechanism, check for issues related to sealing quality. Inspect the sealing components, such as jaws, for wear, misalignment, or damage. Ensure that the temperature settings for sealing are appropriate for the type of packaging material used.

Evaluate Dosing System

If the dosing system is not dispensing paste accurately, inspect the dosing components. Check for clogs, air bubbles, or irregularities that may affect dosing precision. Clean or replace parts as needed and recalibrate the dosing system.

Check For Leaks

Inspect the machine for any leaks, especially in areas where paste is transported. Leaks can affect the accuracy of dosing and compromise the integrity of the packaging. Identify the source of the leak and address it promptly.

Inspect Conveyor And Transport Systems

Examine the conveyor and transport systems for any issues affecting the movement of packaging containers. Check for misalignments, blockages, or malfunctions in the transport mechanisms. Ensure that containers move smoothly through the packaging process.

Evaluate Sensor Functionality

Verify that sensors used for detecting containers, paste levels, or other critical parameters are functioning correctly. Clean or replace sensors that may be obstructed or malfunctioning.

Calibrate Or Adjust

If the machine has calibration features, recalibrate dosing, filling, and sealing systems as needed. Adjust settings based on the specific requirements of the paste product being packaged.

Perform Test Runs

Conduct test runs with the machine using dummy or sample materials. Observe the entire packaging process, from dosing to sealing, and identify any anomalies or irregularities. Make adjustments accordingly.

How Do You Increase the Efficiency of a Paste Packaging Machine

Regular Maintenance

Implement a routine maintenance schedule as recommended by the manufacturer. Regularly inspect and lubricate moving parts, check for wear and tear, and replace any worn components. Preventive maintenance reduces the risk of breakdowns and ensures the machine operates at peak efficiency.

Proper Calibration

Calibrate the dosing system, sensors, and other critical components regularly to maintain accurate measurements and packaging consistency. Calibration ensures that the machine dispenses the correct quantity of paste into each package, reducing waste and improving accuracy.

Optimize Speed Settings

Adjust the machine's speed settings to match the production requirements without compromising accuracy. Striking the right balance between speed and precision is essential for maximizing efficiency. Test different speed settings to find the optimal balance.

Utilize Advanced Controls

If applicable, leverage advanced control features provided by the machine's control system. Automation, programmable logic controllers (PLCs), and advanced software can enhance precision, reduce setup times, and improve overall control over the packaging process.

Efficient Changeovers

Streamline the changeover process when switching between different products or packaging formats. Implement quick-change mechanisms for parts such as dosing systems, forming tools, and sealing components. Efficient changeovers minimize downtime and improve overall productivity.

Monitor And Analyze Performance

Implement a monitoring system to track the machine's performance, including production rates, downtime, and error rates. Analyze performance data to identify bottlenecks, inefficiencies, or recurring issues, and implement corrective measures accordingly.

Optimize Material Usage

Optimize the use of packaging materials to reduce waste. Ensure that the machine is calibrated to dispense the appropriate amount of paste, minimizing overfill and avoiding unnecessary material expenses.

Implement Predictive Maintenance

Explore the use of predictive maintenance technologies, such as sensors and monitoring systems, to anticipate and address potential issues before they lead to equipment failures. This proactive approach helps prevent unexpected downtime.

Ensure Proper Cleaning Procedures

Follow recommended cleaning procedures to maintain hygiene and prevent cross-contamination. Well-maintained and clean machines operate more efficiently and contribute to product quality.

How Do You Repair a Broken Paste Packaging Machine

Inspect for visual signs

Conduct a visual inspection of the machine. Look for any loose connections, damaged components, or obvious signs of wear. Check for spills, leaks, or foreign objects that may be affecting the machine's performance.

Check power supply

Ensure that the machine is properly connected to a stable power supply. Check for any tripped circuit breakers or blown fuses. Confirm that the power source meets the machine's requirements.

Review control settings

Check the control settings on the machine's interface. Confirm that the parameters are correctly set for the specific paste product being packaged. Adjust settings as needed based on the product's viscosity and packaging requirements.

Inspect sensors and switches

Examine sensors and switches that play a role in the machine's operation. Check for proper alignment, cleanliness, and functionality. Malfunctioning sensors can lead to operational issues.

Examine sealing mechanism

If the machine involves sealing, inspect the sealing mechanism for any issues. Check for worn-out or damaged sealing components, and replace them if necessary. Improper seals can result in leaks and compromised packaging.

Evaluate conveyor system

Inspect the conveyor system for misalignments, jams, or obstructions. Ensure that the conveyor is moving smoothly and that there are no issues with product transfer.

Check dosing mechanism

If the machine uses a dosing system, inspect it for accuracy and proper functioning. Adjust dosing parameters if needed to ensure precise filling of paste products.

Review pneumatic systems

If the machine uses pneumatic systems, check for air pressure issues, leaks, or malfunctions. Ensure that pneumatic components such as cylinders and valves are operating correctly.

Monitor temperature controls

For machines with temperature controls, verify that heating elements are functioning as intended. Incorrect temperatures can impact the viscosity of the paste and affect the packaging process.

Inspect hoppers and feeders

Check the paste supply system, including hoppers and feeders, for any clogs or irregularities. Ensure that paste is flowing smoothly through the system.

Identify the cause

Based on the troubleshooting results, identify the specific component or system causing the issue. This will guide the repair process.

Replace faulty components

Replace any damaged or malfunctioning components identified during the troubleshooting process. This may include sensors, switches, seals, conveyor parts, or any other relevant elements.

Adjust settings

Fine-tune control settings, dosing parameters, or other machine settings based on the troubleshooting findings to optimize performance.

Calibrate if necessary

If the machine has calibration features, ensure that they are set correctly. Calibration may be needed for dosing, temperature, or other critical parameters.

Lubricate moving parts

Lubricate moving parts according to the manufacturer's recommendations to ensure smooth operation and prevent wear.

Conduct test runs

After making repairs, conduct test runs to verify that the machine is functioning as intended. Monitor for any issues and make additional adjustments if needed.

Schedule regular maintenance

Establish a regular maintenance schedule to prevent issues and prolong the life of the machine. Follow the manufacturer's recommended maintenance guidelines.

How Do You Adjust the Speed of a Paste Packaging Machine

Identify The Speed Control Mechanism

Locate the speed control mechanism on the paste packaging machine. This could be a digital control panel, a touchscreen interface, a manual dial, or another type of speed adjustment system.

Power Off The Machine

Before making any adjustments, ensure that the paste packaging machine is powered off. This ensures the safety of the operator and prevents any accidental changes to the machine's settings during the adjustment process.

Access The Speed Control Interface

If the machine has a digital control panel or touchscreen interface, power it on and access the speed control section. If there is a manual dial, ensure it is easily accessible.

Select The Desired Speed

Depending on the interface, select or input the desired speed for the paste packaging machine. This can often be done using numerical values or adjusting a slider on a touchscreen. If using a manual dial, turn it to the appropriate setting.

Consider Product Characteristics

Take into account the characteristics of the paste product being packaged when adjusting the speed. Factors such as viscosity, consistency, and the nature of the packaging material can impact the optimal packaging speed. Consult the product specifications and packaging guidelines.

Perform Test Runs

After adjusting the speed settings, perform several test runs with the paste packaging machine. Observe the machine's performance, paying attention to the filling accuracy, seal quality, and overall efficiency. Make further adjustments if necessary.

Fine-tune As Needed

Fine-tune the speed settings based on the results of the test runs. Small adjustments may be needed to optimize the packaging process and ensure consistent and accurate packaging.

Ensure Safety Measures

Always follow safety protocols when adjusting machine settings. If there are specific safety measures or precautions outlined in the manual, adhere to them to prevent accidents or damage to the machine.

Ensure Cleanliness

Before starting the calibration process, ensure that the machine is clean, and there is no residue or leftover paste from previous runs. Clean and sanitize relevant components to prevent contamination.

Prepare Test Materials

Have a batch of the paste or substance that closely represents the product intended for packaging. This ensures that the calibration process simulates actual production conditions.

Check Dosing System Components

Inspect the dosing system components, including pistons, pumps, or augers, for any signs of wear, damage, or misalignment. Ensure that all parts are in good condition.

Adjust Dosing System Settings

Access the machine's control panel or human-machine interface (HMI) to locate the settings related to the dosing system. Depending on the machine's design, these settings may include fill volume, speed, or other parameters.

Weighing Scale Setup

Set up a precision weighing scale capable of measuring the weight of the paste accurately. The scale should be placed in a position where it can capture the filled product from the dosing system.

Initiate Calibration Mode

Some paste packaging machines may have a specific calibration mode or function. Follow the manufacturer's instructions to activate the calibration mode, which may temporarily disable the sealing or cutting mechanisms.

Run Test Cycles

Run a series of test cycles, allowing the machine to dispense the paste into the weighing scale. Ensure that the dosing system is set to the desired volume, and monitor the weight of the dispensed paste.

Adjust Settings As Needed

Compare the actual weight of the dispensed paste to the target weight. If there are variations, adjust the dosing system settings accordingly. This may involve tweaking parameters such as fill time, speed, or other factors affecting dosing accuracy.

Repeat Calibration Runs

Conduct multiple calibration runs to verify the consistency of the dosing system. Make further adjustments as needed until the machine consistently dispenses the correct quantity of paste.

Fine-tune For Production Conditions

Consider factors such as variations in paste viscosity, temperature, or other environmental conditions that may affect dosing accuracy. Fine-tune the calibration settings to account for these variations and ensure reliable performance in real production scenarios.

Record Calibration Parameters

Document the calibration parameters used, including dosing system settings and any adjustments made. This record serves as a reference for future calibration checks and troubleshooting.

Perform Periodic Checks

Regularly perform periodic checks and recalibrations to account for any changes in the machine's performance over time. Factors such as wear on components or variations in paste characteristics can affect calibration.

What Are the Different Types of Paste Packaging Machines Available

Tube filling machines

Tube filling machines are designed to fill and seal paste products into tubes. They are commonly used for packaging products such as toothpaste, creams, gels, and ointments. These machines often include features for accurate dosing and sealing.

Vertical form-fill-seal (VFFS) machines

VFFS machines are versatile packaging solutions that form, fill, and seal bags from a roll of film. These machines are suitable for packaging a variety of products, including pastes. VFFS machines can handle different bag styles, such as pillow bags or gusseted bags.

Horizontal form-fill-seal (HFFS) machines

HFFS machines operate horizontally to form, fill, and seal packages. They are suitable for a range of packaging materials, including pouches. HFFS machines can be used for pastes, liquids, and other products.

Piston filling machines

Piston filling machines use a piston mechanism to accurately measure and dispense paste products into containers. These machines are known for their precision and are often used in industries such as food, cosmetics, and pharmaceuticals.

Auger filling machines

Auger filling machines employ an auger screw to convey and dispense paste or powdered products. These machines are suitable for dosing products with varying viscosities and are commonly used for packaging spices, sauces, and similar products.

Rotary filling machines

Rotary filling machines use a rotating platform to fill containers with paste products. These machines are efficient and can handle high-speed production. Rotary fillers are used in industries such as food processing and cosmetics.

Weight-based filling machines

Weight-based filling machines measure the weight of the product to determine the fill amount accurately. These machines are suitable for packaging pastes with varying densities. They are often used in industries where precise weight control is essential.

Sachet packaging machines

Sachet packaging machines are designed specifically for packaging small amounts of paste products into individual sachets. These machines are commonly used for condiments, sauces, and single-use applications.

Cup filling and sealing machines

Cup filling and sealing machines are designed to fill and seal pre-formed cups with paste products. These machines are often used for packaging yogurt, puddings, and other similar products.

Bag-in-box filling machines

Bag-in-box filling machines are used for bulk packaging of pastes in flexible bags placed inside a rigid box or container. These machines are commonly employed in industries such as food service and industrial applications.

How Do You Install a Paste Packaging Machine

Select An Appropriate Location

Choose a suitable location for the paste packaging machine. Consider factors such as available space, proximity to other production equipment, access for maintenance, and compliance with safety regulations. Ensure the installation area is clean, well-ventilated, and free from obstructions.

Verify Utilities

Confirm the availability and compatibility of necessary utilities such as electrical power, compressed air, and water (if applicable). Ensure that the utilities meet the specifications outlined in the machine's manual.

Prepare the Foundation

If required, prepare a stable foundation for the paste packaging machine. Some machines may need to be anchored to the floor for stability. Follow the manufacturer's guidelines for foundation requirements and anchoring methods.

Unpacking and Inspection

Carefully unpack the paste packaging machine, ensuring that all components are accounted for and undamaged during transit. Inspect the machine for any signs of shipping damage and report any issues to the manufacturer or supplier.

Position the Machine

Position the paste packaging machine in the designated installation area. Use leveling tools to ensure that the machine is installed on a level surface. Adjust the machine's height or leveling feet as needed.

Connect Utilities

Connect the machine to the electrical power source following the specifications outlined in the manual. Ensure that the voltage, current, and other electrical requirements match those recommended by the manufacturer. If the machine uses compressed air or other utilities, connect those as well.

Secure the Machine

Securely anchor the paste packaging machine to the floor, if required. This helps prevent movement or vibration during operation and ensures the stability of the machine.

Check Alignment

Verify that the machine components, such as conveyors, dosing systems, and sealing mechanisms, are properly aligned. Misalignments can affect the accuracy and efficiency of the packaging process.

Install Accessories

If the paste packaging machine includes accessories or optional features, install them according to the manufacturer's instructions. This may include additional modules, conveyors, sensors, or printing systems.

Safety Features Check

Test and verify that all safety features, emergency stop buttons, and interlocks are functioning correctly. Conduct safety checks to ensure a safe working environment for operators.

Perform Initial Test Run

Conduct an initial test run of the paste packaging machine without actual product to ensure that all components are operating smoothly. Check for any unusual noises, vibrations, or malfunctions.

Adjustments and Calibration

Fine-tune the machine's settings and calibration based on the manufacturer's recommendations. Adjust parameters related to dosing, sealing, and other critical processes as needed for the specific characteristics of the paste being packaged.

Final Inspection

Conduct a final inspection to ensure that the paste packaging machine is fully installed, operational, and meeting the specified performance criteria. Address any issues identified during the installation process.

How to Maintain Paste Packing Machine

Daily Maintenance

Cleaning

Clean the machine daily to remove any residue or leftover paste. Pay attention to the dosing system, filling nozzles, and sealing mechanisms. Use appropriate cleaning agents and ensure that the machine is thoroughly sanitized.

Inspect Wear Parts

Check wear-prone components such as gaskets, seals, and O-rings. Replace any parts showing signs of wear to prevent leaks or contamination.

Lubrication

Lubricate moving parts as recommended by the manufacturer. Pay attention to gears, bearings, and other components that require regular lubrication to reduce friction and wear.

Check Conveyor System

Inspect the conveyor system for any misalignments, loose belts, or debris. Ensure that the conveyor operates smoothly to maintain a consistent product flow.

Weekly Maintenance

Dosing System Calibration

Perform a weekly calibration check on the dosing system to ensure accurate dispensing of paste. Adjust settings if necessary to maintain precision.

Inspect Electrical Connections

Check all electrical connections and wiring for signs of wear or loose connections. Ensure that electrical components are secure and functioning correctly.

Sealing Mechanism Inspection

Inspect the sealing mechanisms for any wear, misalignment, or damage. Verify that the seals are consistently providing airtight and secure closures.

Review Sensor And Detection Systems

Test and calibrate sensors and detection systems to ensure they accurately detect packaging material and monitor the filling process. Clean or replace sensors as needed.

Monthly Maintenance

Gearbox inspection

If the machine has a gearbox, inspect it for any oil leaks, and check the oil level. Replace or top up the gearbox oil as per the manufacturer's recommendations.

Check Pneumatic Systems

If the machine utilizes pneumatic components, inspect hoses, fittings, and cylinders for any leaks or damage. Ensure that the pneumatic system operates smoothly.

Inspect Safety Features

Test emergency stop buttons and other safety features to ensure they function as intended. Replace any faulty safety components promptly.

Quarterly Maintenance

Deep cleaning

Conduct a more thorough deep cleaning of the machine, especially in areas that may be less accessible during daily cleaning routines. Remove and clean components as necessary.

Check And Tighten Bolts

Inspect all bolts and fasteners for tightness. Tighten any loose bolts to maintain the structural integrity of the machine.

Review And Update Documentation

Review maintenance records, update documentation, and ensure that all maintenance tasks are being consistently performed. Document any changes or adjustments made during maintenance.

FAQ

Q: What is a Paste Packing Machine?

Q: How does a Paste Packing Machine work?

Q: What materials can Paste Packing Machines handle?

Q: Are Paste Packing Machines suitable for food-grade pastes?

Q: What is the importance of accuracy in Paste Packing Machines?

Q: What are the common types of Paste Packing Machines?

Q: How do I select the right Paste Packing Machine for my business?

Q: What is the typical production capacity of a Paste Packing Machine?

Q: How do I maintain a Paste Packing Machine?

Q: What are the safety considerations when using Paste Packing Machines?

Q: Can Paste Packing Machines be integrated into existing?

Q: How do I troubleshoot common issues with Paste Packing Machines?

Q: How do I clean a Paste Packing Machine?

Q: How do I calibrate a Paste Packing Machine?

Q: What is the lifespan of a Paste Packing Machine?

Q: How do I dispose of waste generated by a Paste Packing Machine?

Q: Can Paste Packing Machines be customized?

Q: What training is required to operate a Paste Packing Machine?

Q: How do I store a Paste Packing Machine when not in use?

Q: How do I transport a Paste Packing Machine?

We're professional paste packing machine manufacturers and suppliers in China, specialized in providing high quality products and service. We warmly welcome you to buy customized paste packing machine at low price from our factory. Contact us for quotation.

automatic form fill machine, automatic continuous sealing machine, fully automatic masala packing machine