Contact Us

- Room 2105, Xingda Garden, No. 122 Tianhua Middle Road, Xingsha Street, Changsha County, Hunan Province

- [email protected]

- +8617788962926

Powder packing machine is an automated industrial apparatus designed for the efficient and precise packaging of powdered substances. These machines play a pivotal role in streamlining the packaging process across various industries, including food and beverage, pharmaceuticals, cosmetics, and chemical manufacturing. The primary function of a powder packing machine is to accurately measure and dispense a predetermined quantity of powdered material into packaging containers, such as bags, pouches, or jars. Equipped with advanced technological features, these machines ensure consistency in the packaging process, reducing human error and enhancing overall production efficiency. Powder packing machines often incorporate mechanisms such as auger fillers, weighing systems, and sealing devices to achieve precision in dosage and packaging. The versatility of these machines allows them to handle a wide range of powder types, from fine spices and additives to pharmaceutical powders, maintaining hygiene and preventing contamination throughout the packaging cycle.

Advantages of Powder Packing Machine

Precision And Accuracy

Powder packing machines are designed to measure and dispense powder materials with high precision. This ensures accurate filling of each package, reducing waste and optimizing the use of the powdered substance.

Consistency In Packaging

Powder packing machines provide a consistent and uniform packaging format. This consistency is crucial for brand identity and customer satisfaction, as consumers expect uniform product presentation and quantity in each package.

Hygiene And Cleanliness

Powder packing machines are designed with materials that are easy to clean and maintain. This helps ensure a hygienic production environment, especially important when dealing with food or pharmaceutical powders where cleanliness is a critical factor.

Versatility and adaptability

Many powder packing machines are versatile and can handle a variety of powder types and packaging formats. They can be easily adjusted or reconfigured to accommodate different product specifications, making them adaptable to changing production requirements.

Coffee Powder Packing Machine

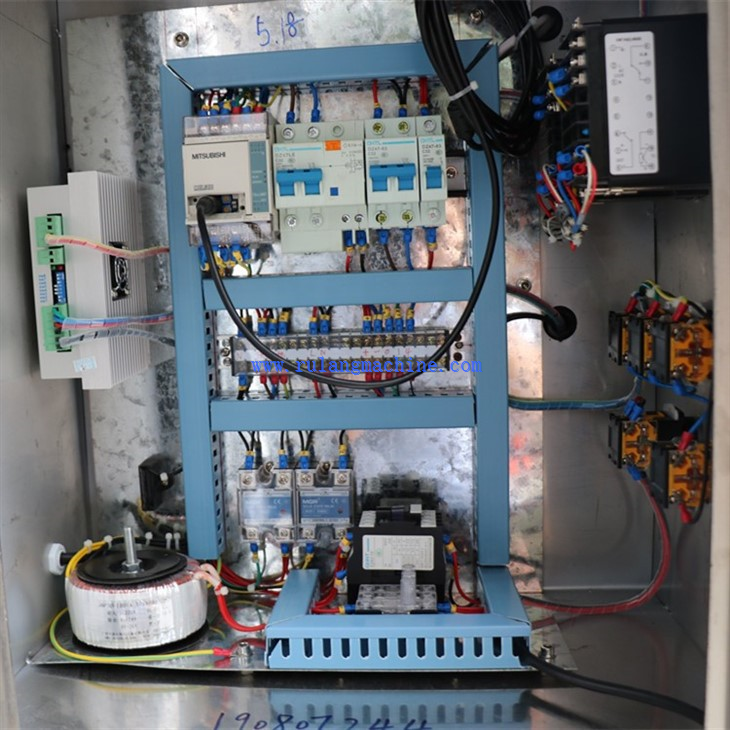

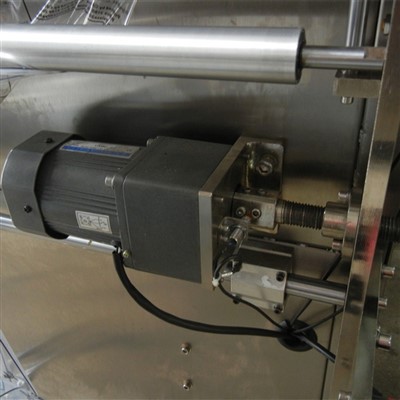

Coffee Powder Packing MachineThe coffee powder packing machine adopt advanced electrical control system and mechanical

Add to Inquiry Automatic Coco Powder Packing Machine

Automatic Coco Powder Packing MachineAutomatically measuring volume, making bags, filling, sealing, cutting, printing the lot number and

Add to Inquiry Multi Line Medicine Powder Packing Machine

Multi Line Medicine Powder Packing MachineUse multi path temperature controlling and heat sealing organ, controlling temperature accurately,

Add to Inquiry Automatic Curry Powder Packaging Machine

Automatic Curry Powder Packaging MachineAutomatically measuring volume, making bags, filling, sealing, cutting, printing the lot number and

Add to Inquiry Automatic Powder Packing Machine

Automatic Powder Packing MachineAutomatically measuring volume, making bags, filling, sealing, cutting, printing the lot number and

Add to Inquiry Coffee Powder Packing Machine

Coffee Powder Packing MachineUse multi path temperature controlling and heat sealing organ, controlling temperature accurately,

Add to Inquiry

Why Choose Us

High Quality

Our products are manufactured or executed to a very high standard, using the finest materials and manufacturing processes.

Professional Team

Our professional team collaborates and communicates effectively with each other, and is dedicated to delivering high quality results. We are capable of handling complex challenges and projects that require our specialized expertise and experience.

Advanced Equipment

A machine, tool or instrument designed with advanced technology and functionality to perform highly specific tasks with greater precision, efficiency and reliability.

24h Online Service

We try and respond to all concerns within 24 hours and our teams are always at your disposal in case of any emergencies.

How to Choose Powder Packing Machine

Type Of Powder

Different powder packing machines are designed for specific types of powders, considering factors such as particle size, flow characteristics, and density. Ensure that the machine you choose is suitable for the physical properties of your powder.

Packaging Material

Consider the type of packaging material you intend to use, such as bags, pouches, or jars. Ensure that the machine is compatible with your chosen packaging material and can deliver the desired sealing and finishing.

Packaging Size And Capacity

Determine the range of packaging sizes and production capacity required for your application. Choose a machine that can handle the desired output while maintaining accuracy in dosing and filling.

Accuracy And Precision

Evaluate the accuracy and precision of the powder packing machine, especially if your product requires specific dosage levels. Look for features such as advanced weighing systems, auger fillers, or volumetric measurement to ensure precise packaging.

Ease Of Use And Maintenance

Opt for a machine with user-friendly controls and interfaces to simplify operation and reduce the risk of errors. Additionally, consider the ease of maintenance, including accessibility for cleaning and routine servicing.

Flexibility And Adaptability

Choose a machine that offers flexibility to accommodate changes in production requirements or different types of powders. Some machines come with adjustable settings or are easily adaptable to varying product specifications.

Integration With Production Line

Ensure that the chosen powder packing machine integrates seamlessly with your existing production line. Consider factors such as the footprint, conveyor compatibility, and overall workflow integration.

Powder packing machine operates through a systematic and precise series of steps, providing an efficient and automated solution for packaging various powdered or granular products. The process begins with the introduction of the powdered or granular substance into the machine, typically through mechanisms like manual loading or conveyor systems. The machine is equipped with a sophisticated weighing or metering system that accurately measures the desired quantity of the powder for each package. This weighing system often utilizes load cells or auger-based metering devices to ensure precision.

Once the product is measured, it is discharged into the chosen packaging material, which can be a pre-formed bag or pouch or, in some cases, a container. If the machine forms bags from a continuous roll of film, a bag-forming step may precede the filling process. The next critical step involves sealing the packaging to preserve the product's freshness and integrity. Sealing can be achieved through various methods, including heat-sealing or ultrasonic sealing, depending on the nature of the packaging material.

In instances where bags are formed from a continuous roll, a cutting mechanism is employed to separate the filled bags, creating individual, sealed packages. The machine may also include quality control features, such as sensors or vision systems, to ensure the accuracy of the fill level and the integrity of the seals. Additionally, some machines may offer options for printing essential information, like date codes or batch numbers, directly onto the packaging.

Throughout the entire process, the powder packing machine operates seamlessly, with careful attention to factors like film tension, alignment, and conveyor speed to maintain accuracy and consistency. The advanced technology integrated into these machines not only streamlines the packaging process but also enhances overall quality control, contributing to the production of well-packaged, visually appealing, and precisely measured products. As a result, manufacturers across various industries rely on powder packing machines to meet their packaging needs efficiently and with a high level of automation.

What Are the Key Features to Look for in a Powder Packing Machine

Weighing System

Reliable and accurate weighing system is crucial for precise measurement of powder quantities. Look for machines equipped with advanced weighing technologies such as load cells or auger-based metering systems to ensure consistent and precise filling.

Packaging Speed

Consider the speed at which the machine can operate, as it directly impacts production efficiency. The packaging speed should align with your production volume requirements.

Packaging Range

Evaluate the machine's flexibility in handling different packaging sizes and formats. The ability to adjust the machine for various bag sizes or containers allows for versatility in packaging different products.

Ease Of Changeover

Machines that facilitate quick and easy changeovers between different products or packaging formats enhance overall production efficiency. Look for features such as tool-less adjustments and intuitive controls.

Packaging Material Compatibility

Ensure that the machine is compatible with the types of packaging materials required for your products. This includes considerations for different film types, thicknesses, and material properties.

Sealing Mechanism

The sealing mechanism is critical for maintaining the freshness and integrity of the packaged powder. Consider the type of sealing method employed, such as heat-sealing or ultrasonic sealing, and assess its suitability for your packaging material.

Quality Control Features

Look for machines equipped with quality control features such as sensors or vision systems. These systems can verify the accuracy of fill levels, detect defects, and ensure the integrity of seals, contributing to overall product quality.

User-friendly Interface

An intuitive and user-friendly interface simplifies machine operation and reduces the learning curve for operators. Touchscreen displays and easy-to-navigate controls enhance overall usability.

Durability And Build Quality

Assess the durability and build quality of the machine to ensure it can withstand the rigors of continuous production. High-quality materials and construction contribute to long-term reliability.

Hygiene And Cleanability

In industries like food and pharmaceuticals, where hygiene is critical, choose a machine with features that facilitate easy cleaning and sanitation. Smooth surfaces, removable parts, and accessibility to critical areas are essential.

Integration Capabilities

If the powder packing machine is part of a larger production line, consider its compatibility with other equipment. Machines with integration capabilities can contribute to a seamless and efficient overall production process.

Safety Features

Prioritize machines with robust safety features, including emergency stop buttons, safety interlocks, and guards. Safety is paramount to protect operators and ensure compliance with industry standards.

Maintenance And Servicing

Evaluate the ease of maintenance and servicing. Machines with features like easy access to components, minimal downtime for maintenance tasks, and comprehensive service and support options can contribute to overall operational efficiency.

Energy Efficiency

Consider the energy efficiency of the machine, especially if sustainability is a priority. Energy-efficient machines can contribute to cost savings and align with environmental considerations.

How Is the Dosing Accuracy Ensured in a Powder Packing Machine

Weighing System

Modern powder packing machines are equipped with advanced weighing systems to measure the precise amount of powder. Common weighing mechanisms include load cells or auger-based metering systems. Load cells detect the weight of the product, while auger systems control the volume of powder dispensed.

Calibration Procedures

Regular calibration of the weighing system is essential to ensure accurate measurements. Calibration involves adjusting the machine to match a known standard, and it should be performed at specified intervals or when there are changes in product characteristics.

Automatic Tare Adjustment

Some machines feature automatic tare adjustment, which compensates for the weight of the packaging material. This ensures that the weight of the actual product is accurately measured, improving overall dosing accuracy.

Closed-loop Feedback Control

Closed-loop feedback control systems continuously monitor and adjust the dosing process in real-time. This helps maintain accuracy by making instant corrections based on variations in product density, flow characteristics, or environmental conditions.

Auger Screw Design

For machines using auger-based metering systems, the design of the auger screw is crucial. The pitch, diameter, and shape of the auger screw can be optimized to achieve consistent and accurate powder flow.

Vibratory Feeders

In some cases, vibratory feeders are used to ensure a consistent and controlled flow of powder into the weighing system. Vibratory feeders prevent clumping and help maintain a uniform powder flow, contributing to dosing accuracy.

Anti-drip Features

Anti-drip features prevent powder residue from affecting subsequent measurements. These features minimize errors caused by powder sticking to the dosing mechanism or spilling after the dosing process is complete.

Quality Control Sensors

Incorporating quality control sensors, such as infrared sensors or vision systems, can verify the fill level and detect any deviations from the target quantity. Sensors contribute to overall quality assurance and dosing accuracy.

Statistical Process Control (SPC)

SPC techniques monitor the dosing process over time, identifying trends or variations that may affect accuracy. SPC allows for proactive adjustments and helps maintain consistent dosing performance.

Machine Design And Stability

The overall design and stability of the powder packing machine play a role in dosing accuracy. A robust and well-engineered machine structure helps minimize vibrations and external factors that could influence dosing precision.

Material Characteristics Consideration

Understanding the characteristics of the powder being handled, such as flow properties, density, and moisture content, is crucial for achieving accurate dosing. The machine's parameters can be adjusted based on the specific characteristics of the powder.

How Do Powder Packing Machines Handle Powders with Varying Densities

Powdered product. The choice of sealing method often depends on the type of packaging material, the characteristics of the powder, and the specific requirements of the product. Here are some common methods of sealing powder packets:

Heat Sealing

Heat sealing is a widely used method for sealing powder packets. It involves applying heat to a heat-sealable packaging material to create a hermetic seal. This process is effective for a variety of packaging materials, including polyethylene, polypropylene, and laminates.

Ultrasonic Sealing

Ultrasonic sealing utilizes ultrasonic vibrations to create a bond between layers of the packaging material. This method is particularly suitable for heat-sensitive powders or when a clean and precise seal is required. It is commonly used in the pharmaceutical and food industries.

Impulse Sealing

Impulse sealing, also known as resistance or heat-wire sealing, involves passing an electrical current through a resistive wire, generating heat to seal the packaging material. This method is often used for thinner films and is suitable for powders that are not sensitive to heat.

Cold Sealing

Cold sealing, or pressure-sensitive sealing, is a method that does not involve heat. Instead, it relies on pressure-sensitive adhesives on the packaging material to create a secure seal. This method is suitable for heat-sensitive powders and is often used in the pharmaceutical industry.

Adhesive Sealing

Adhesive sealing involves applying a layer of adhesive to the packaging material, which is then activated to create a seal. This method is versatile and can be used with various packaging materials, but it may not be suitable for all types of powders.

Zipper Or Resealable Seals

For powders that may be used multiple times, resealable seals with zippers or other closure mechanisms are employed. These seals allow consumers to open and reseal the packet, maintaining the powder's freshness over multiple uses.

Form-fill-seal (FFS) Technology

FFS technology integrates the processes of forming, filling, and sealing into a single continuous operation. This method is commonly used for packaging powders in sachets or small packets, providing an efficient and automated solution.

Inert gas flushing

In some cases, particularly for products sensitive to oxygen, an inert gas flushing step may be incorporated before sealing. This involves replacing the air in the package with an inert gas (such as nitrogen) to extend the shelf life of the powder.

Induction Sealing

Induction sealing involves applying a foil liner to the container or packet, and then using electromagnetic induction to heat and seal the foil to the container. This method provides tamper-evident seals and is often used for powdered products in bottles or jars.

Vacuum Sealing

Vacuum sealing removes the air from the package before sealing, creating a vacuum. This method is suitable for preventing oxidation and preserving the freshness of certain powdered products.

What Are the Energy Consumption Levels of Powder Packing Machines

The energy consumption levels of powder packing machines can vary based on factors such as machine design, features, operational efficiency, and the specific technologies employed. Energy consumption is typically measured in terms of power usage, often expressed in kilowatts (kW) or kilowatt-hours (kWh). Several factors influence the energy consumption of powder packing machines:

Machine Type And Design

Different types of powder packing machines, such as vertical form-fill-seal (VFFS) machines, horizontal form-fill-seal (HFFS) machines, or rotary packing machines, may have varying energy consumption levels. The design and construction of the machine can impact its overall efficiency.

Drive Systems

The type of drive systems used in the machine can affect energy consumption. Modern machines often utilize servo motors or other energy-efficient drive technologies, which can contribute to more precise control and reduced energy usage compared to traditional drive systems.

Automation and Control Systems

Automation features and advanced control systems can optimize machine operation and reduce energy consumption. Smart control algorithms, programmable logic controllers (PLCs), and sensors contribute to more efficient use of energy during different stages of the packaging process.

Efficiency Of Heating Systems

For machines that involve heat sealing or heating elements, the efficiency of the heating systems can influence energy consumption. Advanced heat-sealing technologies and insulation can contribute to more energy-efficient operations.

Packaging Material

The type and characteristics of the packaging material used can impact the energy consumption of the machine. Some materials may require higher temperatures or additional energy for sealing, influencing overall energy usage.

Production Speed

The speed at which the machine operates can affect energy consumption. Higher production speeds may require more energy to drive the machine components and perform various packaging functions. However, the relationship between speed and energy consumption can be complex and depends on the specific machine design.

Idle and Standby Modes

Energy-efficient powder packing machines often include features like automatic idle or standby modes, where energy consumption is reduced when the machine is not actively packaging products. These modes help conserve energy during periods of inactivity.

Energy Recovery Systems

Some advanced machines may incorporate energy recovery systems that capture and reuse energy generated during certain machine processes. This can contribute to overall energy efficiency.

How Does a Powder Packing Machine Handle Static Electricity

Handling static electricity in a powder packing machine is crucial to ensure a smooth and efficient packaging process. Static electricity can lead to various issues, such as powder clinging to surfaces, improper dosing, dust attraction, and even potential safety hazards. Here are ways in which powder packing machines address static electricity

Grounding and bonding

Establishing proper grounding and bonding throughout the machine helps dissipate static charges. Components that come into contact with powders, such as chutes, funnels, and hoppers, are often grounded to prevent the accumulation of static electricity.

Anti-static materials

Using anti-static materials in the construction of machine components and surfaces that come into contact with powders helps minimize the build-up of static charges. Anti-static coatings or materials with inherent anti-static properties can be applied to surfaces.

Ionization systems

Ionization systems release ions (either positive or negative) into the air to neutralize static charges. These systems can be strategically placed in areas where static electricity is likely to occur, effectively reducing the electrostatic forces that attract powders to surfaces.

Humidity control

Maintaining optimal humidity levels in the packaging environment can help mitigate static electricity. Dry conditions tend to promote static build-up, while moderate humidity levels can reduce the likelihood of static charges. However, it's essential to balance humidity control with other factors like powder flow and product quality.

Elimination of sharp edges

Designing machine components with smooth and rounded edges reduces the likelihood of static charge accumulation. Sharp edges can contribute to the generation and retention of static electricity.

Grounding straps and brushes

Grounding straps or brushes can be installed in areas where static build-up is common. These components make physical contact with surfaces, providing a path for static charges to dissipate safely.

Static elimination bars

Static elimination bars, also known as static eliminators or anti-static bars, can be installed at strategic points along the packaging line. These devices emit ions that neutralize static charges on surfaces, preventing the accumulation of static electricity.

Conductive flooring

Utilizing conductive flooring materials in the packaging area can help dissipate static charges that may accumulate on personnel or equipment. Conductive footwear and grounding straps for operators are also employed in some cases.

Proper powder handling

The way powders are handled and fed into the machine can impact static electricity. Minimizing free-fall distances, avoiding rapid powder flow, and using controlled feeding mechanisms help reduce static charges.

Regular maintenance

Implementing a regular maintenance schedule is crucial for ensuring that grounding systems, anti-static components, and ionization systems are functioning effectively. Any accumulation of dust or powder on these components should be promptly cleaned.

What Are the Operational Noise Levels of Powder Packing Machines

The operational noise levels of powder packing machines can vary depending on several factors, including the machine type, design, size, and the specific technologies employed. Noise levels are typically measured in decibels (dB). The following are general considerations regarding the operational noise levels of powder packing machines:

Machine Type

Different types of powder packing machines, such as vertical form-fill-seal (VFFS) machines, horizontal form-fill-seal (HFFS) machines, and rotary packing machines, may have varying noise levels. The specific design and mechanics of each machine type can influence the sound produced during operation.

Drive Systems

The type of drive systems used in the machine, such as servo motors or traditional motors, can impact noise levels. Servo motors are known for their quieter operation compared to some traditional motor systems.

Machine Size And Capacity

Larger machines with higher production capacities may produce more noise due to the increased size of moving components and the power required to drive them. Conversely, smaller machines designed for lower production volumes may generate less noise.

Automation And Control Systems

Advanced automation and control systems can contribute to smoother and quieter machine operation. Precision control and smart algorithms can help optimize movements and reduce unnecessary noise.

Material Handling

The way the machine handles packaging materials and powders can affect noise levels. For example, the movement of conveyors, vibratory feeders, or augers may contribute to the overall noise generated by the machine.

Packaging Material

The type of packaging material used may influence noise levels during the sealing or cutting processes. Some materials may produce more noise when they come into contact with machine components.

Proximity To Operators

Noise levels experienced by operators can depend on their proximity to the machine. Enclosed or sound-insulated areas around the machine can help mitigate noise exposure for operators.

Machine Maintenance

Regular maintenance, including lubrication of moving parts and inspection of wear components, can help minimize vibrations and reduce noise levels over time.

Noise Reduction Features

Some modern powder packing machines incorporate noise reduction features, such as dampening materials, isolators, or sound-absorbing panels, to minimize operational noise.

What Types of Sensors Are Used in Powder Packing Machines

Powder packing machines utilize various sensors to monitor and control different aspects of the packaging process, ensuring accuracy, efficiency, and safety. The types of sensors used can vary based on the specific functionalities and requirements of the machine. Here are common types of sensors employed in powder packing machines:

Photoelectric Sensors

Photoelectric sensors use light beams to detect the presence or absence of objects. In powder packing machines, these sensors are often used for detecting the position of packaging materials, verifying the presence of containers, or monitoring the movement of products on conveyors.

Proximity Sensors

Proximity sensors detect the presence or absence of an object without physical contact. They are often used to sense the position of moving parts or the presence of containers, ensuring precise and timely operations.

Level Sensors

Level sensors monitor the level of powders or granular materials in hoppers or containers. This information helps maintain a consistent supply of product for the packaging process and prevents overfilling or underfilling.

Weight Sensors (Load Cells)

Weight sensors, typically load cells, are crucial for measuring the weight of powdered products during the dosing and filling stages. These sensors ensure accurate and consistent filling of each package.

Infrared Sensors

Infrared sensors are used for detecting the presence of objects or monitoring specific conditions. In powder packing machines, they may be employed for counting products, verifying seals, or detecting anomalies in the packaging process.

Temperature Sensors

Temperature sensors monitor the heat generated during sealing processes, ensuring that the sealing temperature is within the specified range. This helps prevent issues such as incomplete seals or overheating.

Humidity Sensors

Humidity sensors measure the moisture content in the packaging environment. Maintaining optimal humidity levels is crucial for preventing static electricity, controlling powder flow, and ensuring the quality of the packed product.

Vibration Sensors

Vibration sensors are used to monitor the vibrations generated by moving parts in the machine. Excessive vibrations may indicate issues with the equipment or potential malfunctions.

Pressure Sensors

Pressure sensors are employed in various parts of the machine to monitor pressure conditions. For example, they may be used to ensure proper sealing pressure or to detect blockages in the powder flow path.

Capacitive Sensors

Capacitive sensors can detect changes in capacitance, often used for detecting the presence of powdered products or packaging materials. They are sensitive to different material properties and can operate in various environmental conditions.

Encoder Sensors

Encoder sensors are used to monitor the position and speed of moving parts in the machine. This information is crucial for precise control of the packaging process.

Vision Systems

Vision systems, including cameras and image processing technology, are used for quality control. They can inspect the appearance of the packaged product, check for proper seals, and identify defects.

Metal Detectors

Metal detectors are employed to identify and reject packages containing metal contaminants. This is particularly important in industries where metal detection is a critical safety requirement, such as food and pharmaceuticals.

How Do Powder Packing Machines Handle Powders That Are Prone to Clumping

Handling powders that are prone to clumping can be a challenge in powder packing machines, as clumps can lead to inaccurate dosing, uneven filling, and other operational issues. Various strategies and features are employed to address this challenge and ensure the smooth operation of powder packing machines:

De-aeration Systems

De-aeration systems are designed to remove excess air or gases from the powder before it enters the dosing and filling mechanisms. This helps prevent the formation of clumps and ensures a more consistent and free-flowing powder.

Vibratory Feeders

Vibratory feeders use controlled vibrations to ensure a uniform flow of powder. By preventing powder compaction and encouraging a more even distribution, vibratory feeders contribute to the prevention of clumping.

Agitators And Stirrers

Some powder packing machines are equipped with agitators or stirrers in hoppers or dosing chambers. These components prevent powder particles from settling and forming clumps by maintaining a consistent and homogeneous powder mixture.

Auger Design

The design of the auger (screw) used for powder dosing is crucial. Augers with specialized shapes or configurations can help break up clumps and ensure a smoother powder flow. Multi-flight or tapered augers are examples of designs that aid in preventing clumping.

Anti-clumping Devices

Some machines may incorporate anti-clumping devices, which could include rotating brushes or paddles that gently break up clumps and promote a more even powder flow.

Powder Conditioning

Pre-conditioning the powder by adding anti-caking agents or using processing techniques to improve the flow properties can be effective in reducing the likelihood of clumping. These measures can be implemented upstream in the production process.

Variable Speed Augers

Adjustable auger speeds allow operators to fine-tune the dosing mechanism based on the characteristics of the powder being processed. Slower speeds can be beneficial for delicate powders that are prone to clumping.

Real-time Monitoring And Feedback

Some advanced powder packing machines use sensors and monitoring systems to detect irregularities in powder flow. Real-time feedback allows the machine to adjust its operation, such as slowing down the dosing mechanism, in response to detected clumping.

Airflow Control

Controlling the airflow within the dosing and filling areas can help minimize powder clumping. Strategic placement of airflow control mechanisms can ensure that powders are delivered smoothly without forming clumps.

Closed-loop Control Systems

Closed-loop control systems continuously monitor and adjust dosing parameters based on real-time feedback. These systems can dynamically adapt to changes in powder characteristics, helping to prevent and address clumping issues.

Regular Cleaning: Clean the machine regularly to remove any powder residues, dust, or debris. Pay attention to critical areas such as dosing chambers, hoppers, conveyors, and sealing mechanisms. Use appropriate cleaning methods and ensure that the machine is powered off during cleaning.

Inspect Wear Parts: Regularly inspect wear parts, such as sealing bars, cutting blades, and augers. Replace any components that show signs of wear to prevent operational issues and maintain the quality of seals and cuts.

Lubrication: Follow the manufacturer's recommendations for lubricating moving parts. Proper lubrication reduces friction, minimizes wear and tear, and ensures smooth machine operation. Use the specified lubricants in the recommended quantities.

Check And Tighten Fasteners: Regularly check and tighten bolts, nuts, and other fasteners to prevent loosening during operation. Vibration and continuous use can cause fasteners to become loose over time.

Calibration and adjustment

Calibrate the machine regularly to ensure accurate dosing and filling. Check and adjust settings as needed to align with the characteristics of the powder being processed. This is crucial for maintaining accurate product weights and packaging consistency.

Inspect electrical components

Inspect electrical components, such as wiring, connectors, and sensors, for signs of wear, damage, or loose connections. Address any issues promptly to prevent electrical malfunctions.

Check and replace seals

Inspect seals regularly, especially those involved in the packaging process. Damaged or worn seals can compromise the integrity of the packaging and lead to product contamination. Replace seals as needed.

Monitor and adjust tension

Regularly check the tension of belts and chains. Proper tension ensures smooth operation and prevents slippage or misalignment of components. Adjust tension according to the manufacturer's specifications.

Inspect pneumatic systems

If the machine utilizes pneumatic components, inspect hoses, connectors, and valves for leaks or damage. Ensure that air pressure is within the recommended range for optimal performance.

Monitor sensor performance

If the machine is equipped with sensors, monitor their performance regularly. Clean sensors and ensure they are properly calibrated to detect powder flow, fill levels, and other critical parameters accurately.

FAQ

Q: What is a Powder Packing Machine?

Q: How does a Powder Packing Machine work?

Q: What types of powders can be handled by a Powder Packing Machine?

Q: What are the advantages of using a Powder Packing Machine?

Q: Can a Powder Packing Machine handle different packaging materials?

Q: How is the accuracy of powder filling ensured?

Q: Is the machine suitable for packaging fine powders?

Q: What is the speed range of a typical Powder Packing Machine?

Q: Can a Powder Packing Machine handle packaging in different weight ranges?

Q: How is the hygiene maintained in a Powder Packing Machine?

Q: What is the role of the dust extraction system in a Powder Packing Machine?

Q: Can a Powder Packing Machine handle packaging with nitrogen flushing?

Q: What training is required for operators to run a Powder Packing Machine?

Q: How are product jams or blockages handled in a Powder Packing Machine?

Q: Can a Powder Packing Machine handle packaging with multiple powders in a single pack?

Q: What safety features are incorporated into Powder Packing Machines?

Q: Can a Powder Packing Machine handle packaging with variable powder densities?

Q: How is the film quality monitored during the packaging process?

Q: How is the machine cleaned and sanitized between different powder types?

Q: Can a Powder Packing Machine be integrated with other packaging equipment?

We're professional powder packing machine manufacturers and suppliers in China, specialized in providing high quality products and service. We warmly welcome you to buy customized powder packing machine at low price from our factory. Contact us for quotation.

washing powder pouch packing machine, semi auto weighing filling machine, auto vacuum packing machine