Contact Us

- Room 2105, Xingda Garden, No. 122 Tianhua Middle Road, Xingsha Street, Changsha County, Hunan Province

- [email protected]

- +8617788962926

Why Choose Us

Excellent Product Quality

Our enterprise mainly produce fiber-reinforced resin bond abrasive grinding wheel, cutting disc and power tools.

Rich Experience In Production

With economical solutions, excellence performance machines and perfect after-sales services, we has always been.

After-Sales Service

Good after-sale service, handling the customer complaint and solve problem for customers. Customer first.

Innovation

We are dedicated to improving our systems Machinery continually, ensuring that the technology we offer is always cutting edge.

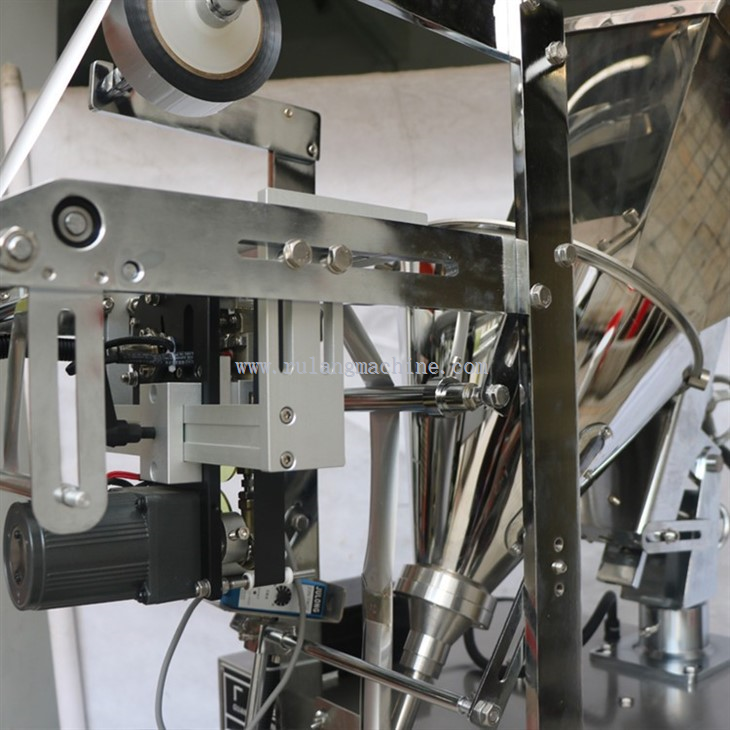

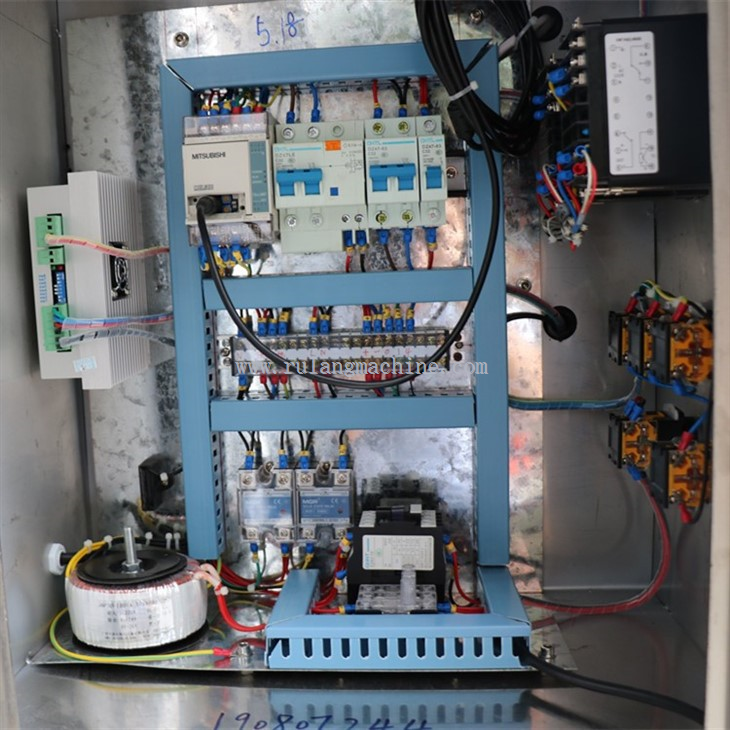

An automatic packaging machine is a sophisticated piece of equipment designed to automate the process of packaging products into various types of containers or packages. These machines are widely used in the manufacturing industry to improve production efficiency, ensure consistency, and reduce labor costs.

Juice Packing Machine

Juice Packing MachineThe automatic juice packing machine is the equipment that can automatically complete the whole

Add to Inquiry Horizontal Flow Packing Machine

Horizontal Flow Packing MachineThe horizontal flow packing machine is an efficient automatic packaging machine. It is suitable for

Add to Inquiry Coffee Powder Packing Machine

Coffee Powder Packing MachineThe coffee powder packing machine adopt advanced electrical control system and mechanical

Add to Inquiry Automatic Sauce Packing Machine

Automatic Sauce Packing MachineAn automatic sauce packing machine is a type of packaging machinery specifically designed to

Add to Inquiry Automatic Salt Packing Machine

Automatic Salt Packing MachineAutomatic salt packing machine provides all operations such as automatic bagging, filling,

Add to Inquiry Full Automatic Chilli Sauce Paste Sachet Packaging Machine

Full Automatic Chilli Sauce Paste Sachet Packaging MachineThe Full Automatic Fruit Jam Vertical Forming Filling Sealing Machine is a state-of-the-art

Add to Inquiry Full Automatic High Speed Solid Drinking Packaging Machine

Full Automatic High Speed Solid Drinking Packaging MachineIt is use volumetric cups measure the weight and dosing.Suit filling granule product

Add to Inquiry Multi Track Juice Ice Popcicle Packaging Machine

Multi Track Juice Ice Popcicle Packaging MachineFunction: Full automatic dosing filling forming sealing printing date machine. Famous brand PLC

Add to Inquiry Full Automatic Fruit Jam Vertial Forming Filling Sealing ...

Full Automatic Fruit Jam Vertial Forming Filling Sealing ...The Full Automatic Fruit Jam Vertical Forming Filling Sealing Machine is a state-of-the-art

Add to Inquiry Automatic Disposible Fork Knife Spoon Packing Machine Pac...

Automatic Disposible Fork Knife Spoon Packing Machine Pac...Disposable Plastic Wooden Spoon Fork And Knife Automatic Packaging Machine Cutlery Set With Napkin

Add to Inquiry Multi-track Coffee Packing Machine

Multi-track Coffee Packing MachineIt is use volumetric cups measure the weight and dosing.Suit filling granule product

Add to Inquiry Automatic Ice Pop Liquid Packing Machine

Automatic Ice Pop Liquid Packing Machinethe ice pop packing machine is highly efficient. It minimizes wastage of resources such as plastic

Add to Inquiry

Benefits of Automatic Packing Machine

Quality: Automated systems are accurate and consistent because they have precise, standardized settings. They help improve product quality, cycle time and operations in general.

Productivity: Manually packaging pallets, boxes and other products can be difficult and time-consuming. Your workers may become tired from the repetitive, monotonous and strenuous activity. Machines can work much longer at full efficiency. They also offer much higher speeds.

Product care: If you use the right machinery, your products can be securely packaged. For example, a good stretch wrapping machine will ensure that the products are well-wrapped and safe from contamination. This increases the durability and shelf life of products.

Low wastage: Machines are economical in using packaging material. They cut the material precisely and maximize its use by using well-defined patterns. This streamlines the packaging process and reduces waste of materials.

Sustainability: Many original equipment manufacturers (OEMs) now manufacture packaging machinery with sustainability in mind. Such machinery not only offers good return on investment (ROI), but also is beneficial for the environment. They use fewer materials and have lesser greenhouse gas emissions.

Specialized packaging: If you have many products and different packaging sizes, a semi-automated solution would suit you better than a wholly automated one. Regardless of how diverse your products are, you can find suitable packaging machinery for it. Moreover, by automating packaging, you can change the outline for a case or pallet quickly.

Major Benefits of Automated Packaging

Reduces The Risk Of Repetitive Strain Injury

Repetitive strain injury risks are lowered when products are packed automatically rather than manually. This is due to the fact that automation removes the need for human input to complete repetitive manual tasks.

Eliminate Potential Bottlenecks

Manual packaging processes can often lead to bottlenecks within a production process when human errors occur. Automated packaging processes can help to eliminate this bottleneck as a bespoke machine will be designed to keep up with the flow off the production line. With automated packaging there is also less scope for packaging errors, which in turn leads to less downtime and bottlenecks.

Improved Production Speed

Automating your packaging process can lead to improved production speeds. Often when there is a manual packaging process, the machine producing the product is not able to run at full capacity as the manual packaging process is not able to keep up with this level of output. By automating the packaging of the products you are then able to remove this constraint and improve your production speed.

Eliminate Downtime

As with any process involving manual labour, staff are entitled to breaks. Often in factories this means that production stops during these breaks resulting in downtime and loss of production. With an automated packaging solution, these breaks no longer happen, and the machines can be run 24/7 if required.

Types of Automated Packaging

Automatic Premade Stand Up Zipper Pouch Baking Soda Packing Machine

The Automatic Premade Stand Up Zipper Pouch Baking Soda Packing Machine is a state-of-the-art packaging solution for baking soda. It automates the entire packaging process, ensuring consistent results and easy storage for consumers. Ideal for baking soda manufacturers looking to boost productivity and packaging efficiency.

Automatic Nuts Coffee Bean Premade Standup Pouch Packing Machine

The Automatic Nuts Coffee Bean Premade Standup Pouch Packing Machine is a state-of-the-art packaging solution. It automates the entire process, from filling standup pouches with nuts and coffee beans to securely sealing them. The machine ensures precise and efficient packaging, preserving the freshness and quality of the contents. Perfect for nut and coffee bean manufacturers aiming to enhance productivity and deliver superior packaged products to customers.

Automatic Clay Mask Powder Filling Sealing Packaging Machine

The Automatic Clay Mask Powder Filling Sealing Packaging Machine is a state-of-the-art solution for packaging clay mask powder. It automates the entire process, from filling the powder into containers to securely sealing them. This efficient machine ensures the preservation of the powder’s properties and quality, making it an ideal choice for clay mask manufacturers seeking increased productivity and superior packaging capabilities.

2.2lbs Biological Compost Fertilizer Zipper Bag Packing Machine

The 2.2lbs Biological Compost Fertilizer Zipper Bag Packing Machine is a state-of-the-art packaging solution. It automates the process of filling 2.2lbs of biological compost fertilizer into zipper bags and securely sealing them. This efficient machine ensures precise measurements and consistent packaging, preserving the fertilizer’s quality and effectiveness. Perfect for manufacturers looking to enhance productivity and deliver their products in user-friendly and sustainable packaging.

Application of Automated Packaging

Packaging machines are used to package products or components. This product area includes equipment that forms, fills, seals, wraps, cleans, and packages at different levels of automation. Packaging machines also include related machinery for sorting, counting, and accumulating.

Maintenance Automated Packaging

To make your maintenance process as efficient as possible, start with developing your procedures beforehand and implement them on a recurring basis. With safeguarding and monitoring, you can conduct the correct maintenance but also be sure that you should keep the machine well-cleaned and operational.

Periodic maintenance prevents problems, extends the lifespan and saves money. A failure in a packaging machine can cause a complete production line to come to a standstill. Instead of dealing with logistical headaches, developing a sound routine can prevent downtime associated with repair and replacing parts.

Preventive lubrication

The user is responsible for the moving parts of the machine. They must be kept lubricated regularly and provided with a drop of lubricant, as described in the machine manual. If this preventive lubrication is neglected, defects resulting from friction are usually not covered by warranty.

Keep the machine clean

Periodic cleaning, when done often, can prevent long periods of downtime associated with more intense, less-frequent maintenance. Dirty machines are unpleasant to use and work on. If the machine is covered in dust, dirt, and debris, it may also mask some potential problems with its functionality.

Machine inspection

Regular inspection is key to ensuring a long lifespan for your machine. If the problem is caught early, it may lead to a timely and inexpensive fix, but the longer the problem lingers on, the higher the price is likely to be.

Routine inspection will ensure that the machine still produces to the same accuracy and efficiency standard as it did on the first day you bought it. Recurring examination of all machine parts can help reduce repair downtime and drive bottom line savings for your business.

Changing parts regularly

Packaging machine parts can wear down from recurring use. To ensure that the machine is working to its full potential, you should be well aware that the parts will need changing regularly to avoid any slowing down of the mechanisms or failure altogether.

To reduce downtime, you should familiarize yourself with the types of parts used on your machines and the process of changing the spare parts. These parts fall into three categories:

High-wear parts. These parts have a short lifecycle.

- Medium-wear parts: They have a longer life cycle and may or may not ever fail.

- Low-wear parts: These parts should never fail.

- These part changes may coincide with an upgrade for your machine components, in which case you should keep up good communication with your provider to ensure that there is no recommended upgrade needed in the coming months. This will result in a better-performing packaging machine.

Certifications

Our Factory

The company is located in Changsha central of China, only half hour drive from Changsha Huanghua International Airport with convenient transportation and beautiful environment. Welcome to visit our company

FAQ

Q: How does automated packaging work?

Q: What are the benefits of using automation in packaging industry?

2 - Better Protected Products.

3 - Designed To The Requirements.

4 - Improvement In Quality Control.

5 - Increased Production Speed.

6 - Improved Safety.

7 - Improves Customer Service.

8 - Eliminates Any Downtime.

Q: What are the types of automated packaging?

Filling Machines.

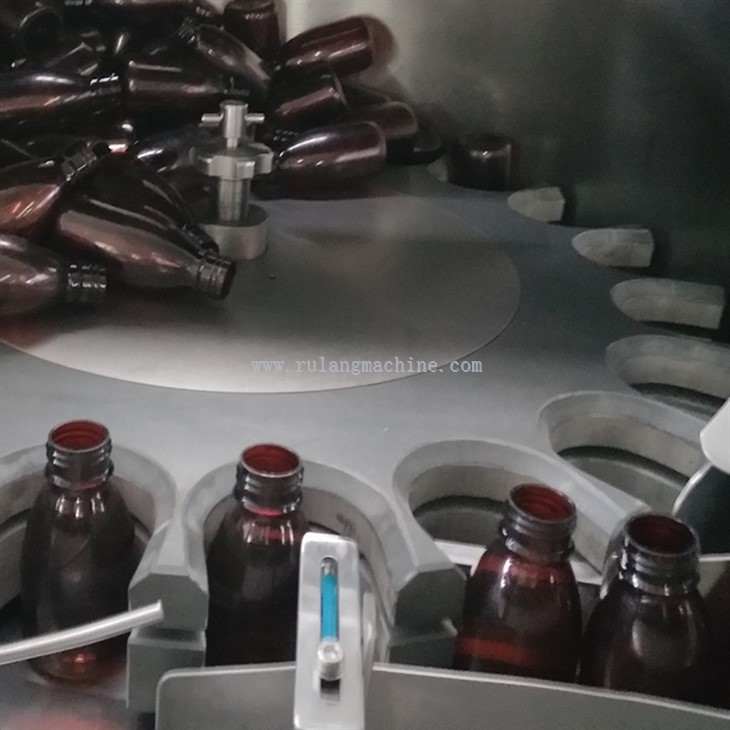

Pharmaceutical Packaging.

Wrapping and Sealing Machines.

Labelling Machines.

Packing and Palletizing Machines.

Q: Which type of automation is preferred for packaging industry?

Q: What are intelligent packaging techniques?

Q: What are 4 benefits of automation?

Q: What is AI in packaging?

Q: What is the difference between smart and intelligent packaging?

Q: What are limitations of automation?

Q: What is the main goal of automation?

Q: Why do we need automation?

Q: How does automation increase productivity?

Q: What is the future of packaging?

Q: What is the principle of smart packaging?

Q: Does automation reduce workload?

Q: When should automation be used?

Q: What is the simplest form of automation?

Answer: The simplest form of automation is Robotic Process Automation (RPA). Explanation: Robotic process automation assists businesses in streamlining operations and boosting long-term productivity and profitability.

Q: What is active and intelligent packaging?

Q: How is AI used in automation?

Q: How has automation changed the world?

We're professional automatic packing machine manufacturers and suppliers in China, specialized in providing high quality products and service. We warmly welcome you to buy customized automatic packing machine at low price from our factory. Contact us for quotation.

sejong tablet compression machine, semi auto sealing machine, industrial vinyl sticker printer