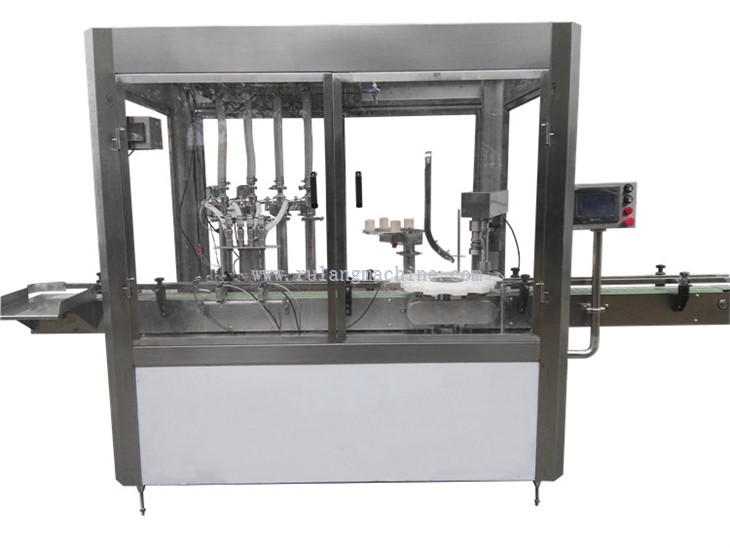

The edible oil filling machine is an equipment for packaging edible oil products and is highly trusted by customers.

With the passage of time, the variety of edible oil products has become increasingly diverse, and the packaging forms of products have also changed greatly. However, regardless, the application of edible oil filling machines is irreplaceable. The technical performance of edible oil filling machines has greatly improved, especially in terms of filling accuracy, with strict control and improvement. However, in addition, there are many common problems that require manufacturers to be careful and control when operating the edible oil filling machine.

1, The edible oil filling machine experiences dripping after being turned off for use. After the completion of production, if there is dripping phenomenon in the edible oil filling machine, it should be operated from the following aspects:

1. Check if the filling nozzle hole is damaged, and remove the filling nozzle to repair the hole. The diameter of the hole should be less than 7.5mm. After repairing the aperture, gently grind the flat surface of the hole on a water frosted paper.

2. Check if the ball valve inside the filling head is damaged, and replace it promptly.

What should be done if the crank of the edible oil filling machine does not operate properly after starting up?

The fixing rod on the edible oil filling machine is leaning downwards, and the inner and outer tubes of the syringe are firmly pressed when pushing the liquid, causing the crank to not rotate. The nut should be loosened, and the upper fixing rod should be moved up to the appropriate position before tightening the nut. If the assembly of the syringe causes the inner and outer tubes to become uncleaned and stuck, the syringe needs to be disassembled for cleaning. Observe the end of the injection system at the bearing location. To prevent it from working properly, it must be reinstalled.

Thirdly, if there is a capacity error or a large capacity error in the edible oil filling machine, what adjustments need to be made?

There is air in the liquid pipe of the edible oil filling machine. Press the foot switch more often to exhaust. The inlet pipeline is not tightly sealed and there may be air leakage. Tighten the connecting pipe. If the operation or filling speed is too fast, slow down the speed appropriately. The liquid level in the material tank is low, and the liquid level should be 1.52 meters. When filling large specifications, insufficient filling in the material tank can cause unstable liquid level. To increase the amount of filling or close the ball valve above the filling head again, reset the filling time (extend)